Business

Facilities

01

Self-development of mold

-

DEIGN 설계

Zero defect mold

Ultra-precision mold design

Self-design, quick response

Quick on-site correspondence

-

manufacture 가공

Systematic process system

Possess W/C processing technology

Ultra precision machining

-

measurement 측정

Zero defect outflow system

-

assemble 조립

Zero defect mold assembly

Unmanned system

100% clean washing technology

02

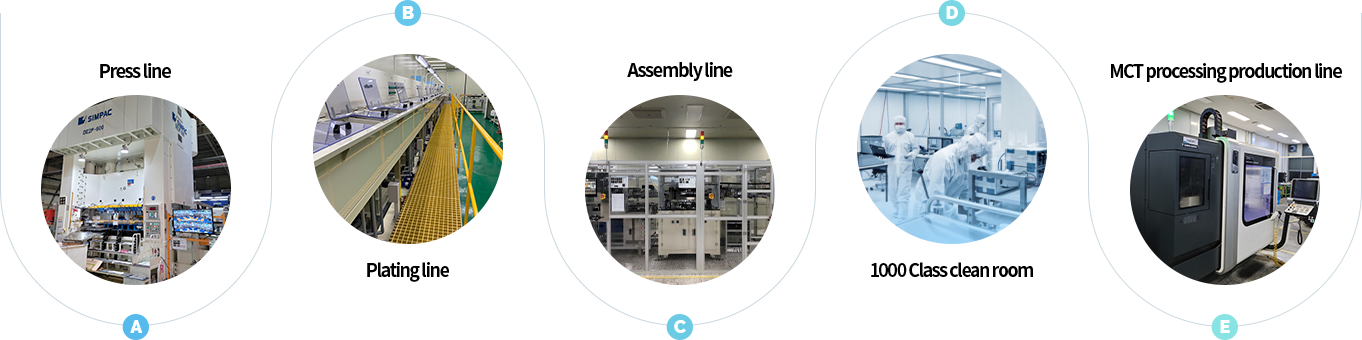

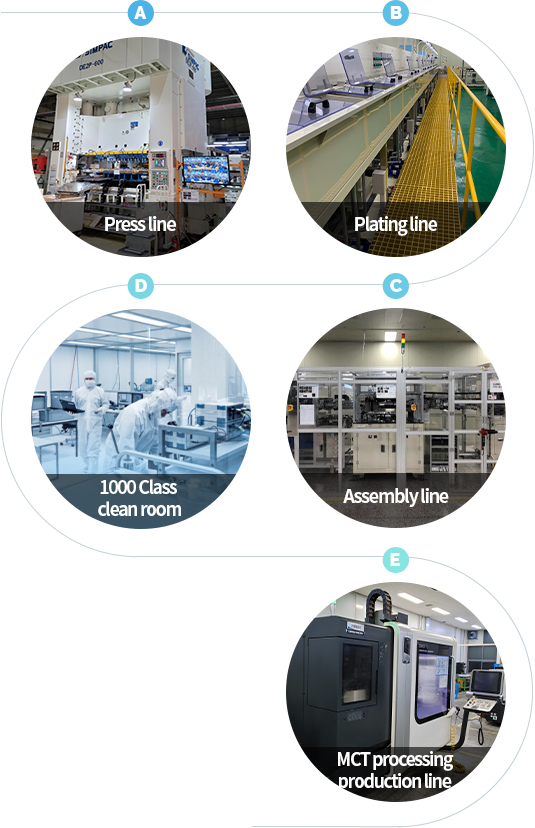

Domestic manufacturing Facilities

Manufacturing Facilities

Main facilities status

| Facility | Ton | Line | Remarks |

|---|---|---|---|

| Progressive Line | 600 | 1 | Transfer |

| 200 - 250 | 5 | Knuckle Press | |

| 80 - 100 | 2 | KYORI / Knuckle Press | |

| 40 - 60 | 10 | KYORI / Knuckle Press | |

| Injection Line | 280 | 1 | ENGEL |

| MCT Processing Line | 5th line~ 8th line | 5 | 5 Axis : 2 / 3 Axis : 3 |

| Plating | Rack / Reel To Reel | 4 / 4 | NEX APL (Affiliate) |

03

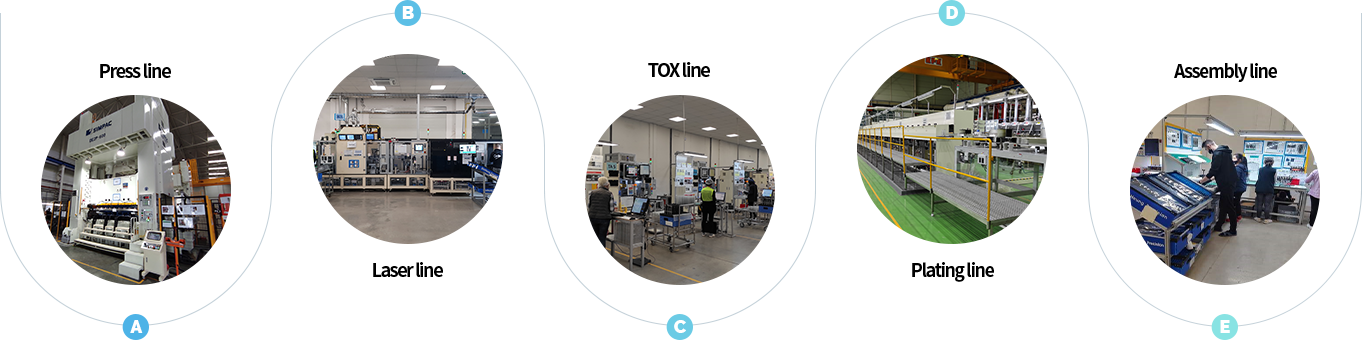

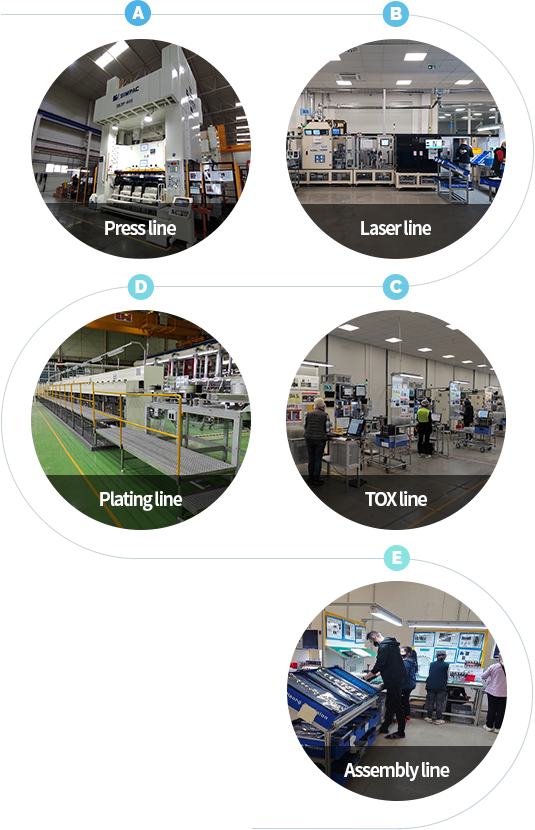

Overseas manufacturing Facilities

Manufacturing Facilities

Main facilities status

| Overseas | Name of facility | Spec.(Ton) | Number of line | Remark |

|---|---|---|---|---|

| Slovakia | Press (Robot Line) | 200 - 300 | 15 | |

| Press (Single Line) | 60 - 80 | 3 | ||

| Ultra wash | - | 1 | 3 Type | |

| Ultra wash | END | 5 | 3 | |

| Busbar | 2 | |||

| Assembly Line | END | 1 | ||

| Side | 8 | Jig | ||

| HBB | 3 | |||

| TOX | 10 - 20 | 7 |

04

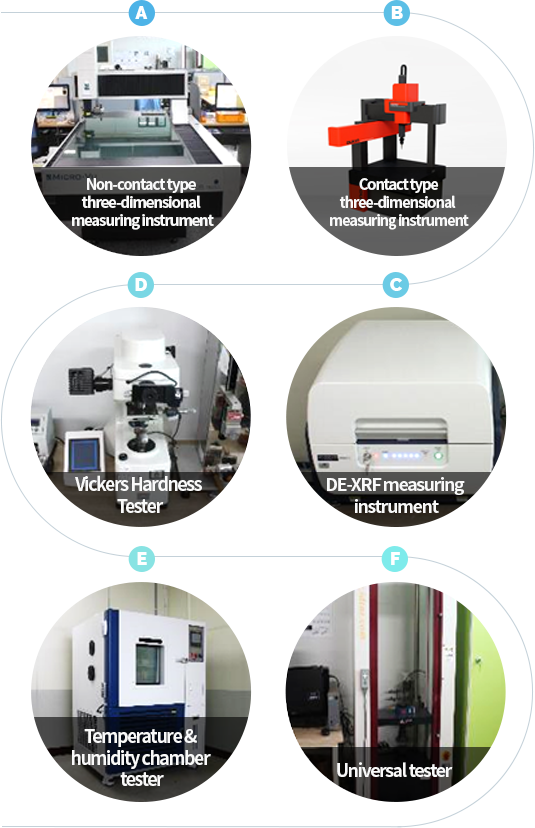

Quality Facilities

Quality facilities status

| Classification | Name of instrument | Purpose of use | NEX | NSK |

|---|---|---|---|---|

| Measuring instrument | Non-contact type three-dimensional measuring instrument | Product Shape, Non-contact type three-dimensional measuring | 4 | 3 |

| Contact type three-dimensional measuring instrument | 1 | 1 | ||

| Reliability | DE-XRF measuring instrument | Non-destructive analysis of environmentally hazardous substances | 1 | 1 |

| Vickers Hardness Tester | Measuring material hardness | 1 | 1 | |

| Temperature & humidity chamber tester | Temperature/humidity performance test | 1 | ||

| Universal tester | Stretching test | 1 | 2 | |

| Salt spray tester | Corrosion Test | 1 | 1 |